Processing Technology

High-performance cleaning machines made by Franz Ruberg & Co. GmbH are used for the reception and cleaning of various bulk materials: grain, maize, oil seeds, barley , malt, coffee, paddy rice, soybeans and the like. During coarse cleaning, directly following the goods intake, any foreign matter like pieces of wood or stones are separated, as they might damage any downstream machines, such as conveying systems. Due to a thorough yet gentle cleaning process, the quality of the final product is maintained and optimum storage properties are ensured. It also prevents the development of any harmful substances or toxic fungi. Used in combination with our fan, filter and dedusting components, we meet current safety and environmental regulations and guarantee an effective and trouble-free operation of Franz Ruberg & Co. GmbH cleaning machines.

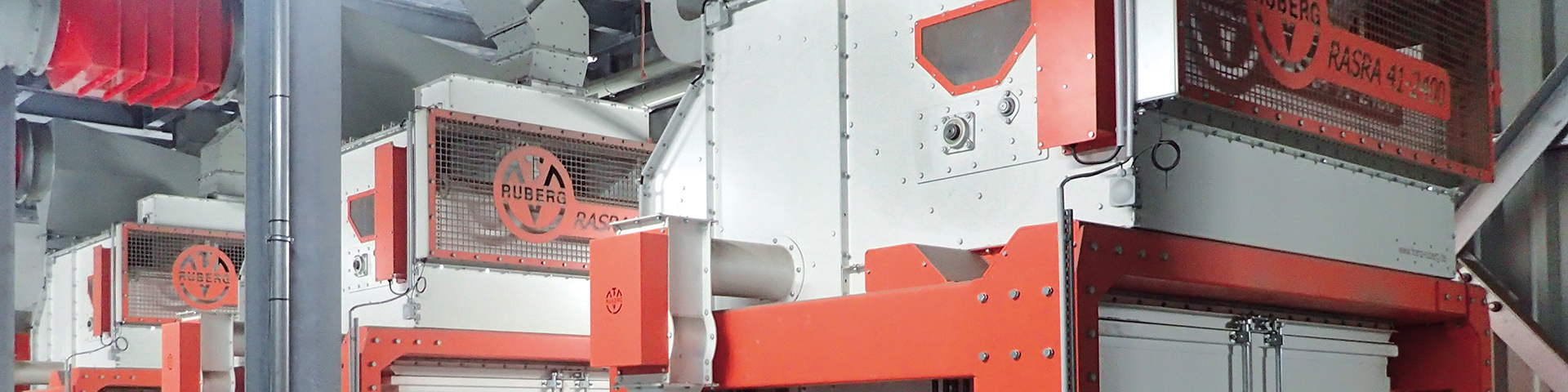

RASRA Cleaning Machines

Pre- and main cleaning in top quality

Our cleaning machines of the RASRA series guarantee a high throughput rate and optimal cleaning results. Based on our long standing experience in the field of grain processing, we were able to develop a machine type that combines two cleaning functions: aspiration and screen cleaning.

Due to the double aspiration, dust and other light particles are removed. Coarse particles are separated by means of the upper screen decks. Additionaly the grain is separated into two fractions: the first grade final product and the brokens resp. small grains.

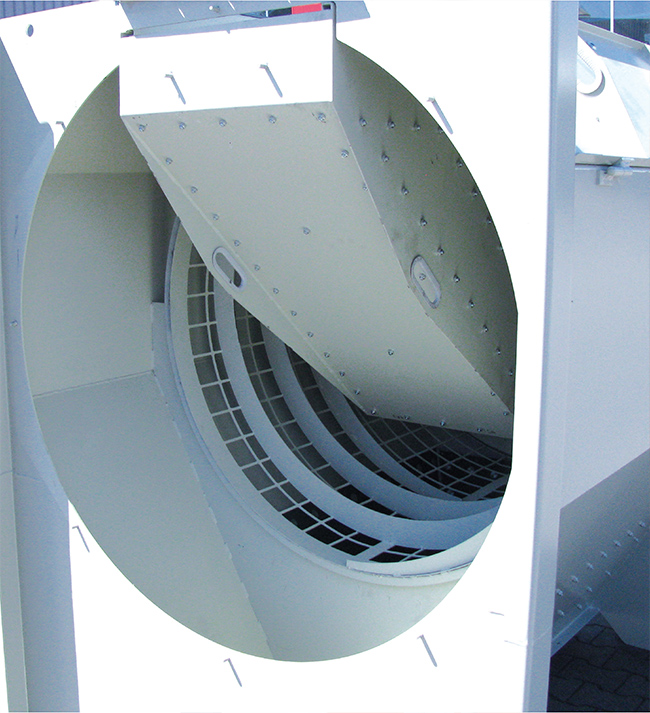

Drum Screening Machine

Drum screens are primarily used for the coarse cleaning. Impurities in the harvested crop or in similar products reduce the quality and adversely affect the further processing. Ruberg drum screens reliably separate unwanted coarse foreign matter and thus improve the product quality. At the same time they prevent any damage to the machines and conveying systems of the downstream processing line.

Air Classifiers

In the air column of the air classifier all light particles like dust, chaff and husks are reliably separated. Unwanted material is aspirated and discharged via a special conveyor line. The heavy grains continue their downward path out of the sifter.

Air classifiers can be used for various products in the food and grain industry.

Disc Screens

Disc screens are ideally suited for the sorting of many different materials in applications demanding high throughput capacities. Due to their sturdy design, disc screens are extremely robust and guarantee high operational reliability.

Disc screens have also proven to be very effective in the sorting of reusable materials in the recycling industry, e.g. in the pre-sorting of paper and cardboard, industrial waste, construction waste or wood chips.